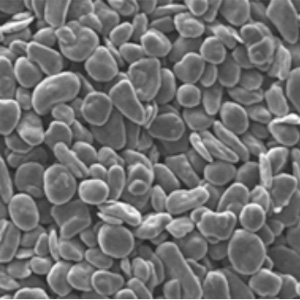

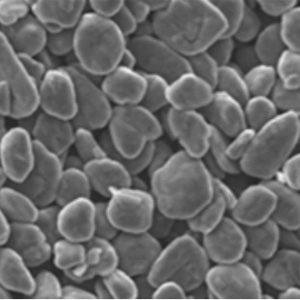

HG-195

HG-195 is made by natural graphite powder as raw material. As a negative electrode material for lithium-ion batteries, it has gone through a series of technology such as machining, coating modification,chemical modification treatment and high-temperature heat treatment. Striving to meet customer demands for higher capacity and compact anode materials.

Main Features:

1. High capacity and compact density

2. Excellent performance in the process

3. low irreversible capacity

4. Extremely low coefficient of expansion

5. Good performance in the process

6. Good performance at low temperatures

Performance:

Item | Unit | Internal control index | Typical value | Testing instrument |

Particle Size Distribution(D50) | μm | 11.0~14.0 | 12.55 | Malvern Instruments Ltd Model:Mastersizer2000 |

Tap Density | g/ml | ≥0.95 | 1.02 | Steel Research Institute :FZS4-4B |

Surface Are | m2/g | ≤2.30 | 2.12 | Beijing Jingwei Gaobo Science And Technology Co., Ltd. Model: JW004A |

Real Density | g/cm3 | ≥2.20 | 2.23 | Pycnometer Method |

Ash Content | % | ≤0.10 | 0.03 | Shenyang Energy Saving Electric Furnace Factory Model: SRJX-4-13 |

Compact density | g/cm3 | 1.62~1.75 | 1.64 | Guangzhou Lange Electric Co., Ltd Model:CLG-ZM-400Y |

Specific Discharge Capacity | mAh/g | ≥360.0 | 364.8 | ArbinBattery Test System / Blue Battery Test System Model: CT-3008W-5V1mA |

First Discharge Efficiency | % | ≥93.0 | 93.6 |

Application:

It is applied to high energy density cylindrical batteries. It can also be applied to steel and aluminium casing, liquid flexible packaging, polymer and other batteries.

If you are interested in our product, please enquire us for more details.